Rotary Arm Drum Filler for 200L Containers - Heavy-Duty Liquid Packaging Machinery2

A Rotary Arm Drum Filler for 200L Containers is a specialized, heavy-duty liquid packaging machine designed to efficiently and accurately fill large containers such as 200L drums, IBCs (Intermediate Bulk Containers), or similar industrial vessels. This equipment is widely used in industries where bulk liquid handling is critical, such as chemicals, food and beverage, pharmaceuticals, oils, and lubricants. Here's a detailed overview of its key features, benefits, and applications:

Key Features of Rotary Arm Drum Filler Machines

Rotary Arm Design:

A rotating arm with a precision-controlled nozzle ensures accurate filling without spills or splashes.

The arm follows a programmed path to maintain consistency and minimize product waste.

Heavy-Duty Construction:

Built with high-strength materials (e.g., stainless steel) to withstand harsh industrial environments.

Corrosion-resistant and suitable for aggressive or hazardous liquids.

High-Speed Filling:

Capable of filling 200L drums quickly, with speeds ranging from 10 to 30 drums per hour depending on configuration.

Ideal for high-volume production lines.

Precise Volumetric or Gravimetric Control:

Uses flow meters or load cells to ensure accurate filling by volume or weight.

Minimizes overfilling or underfilling, ensuring compliance with regulatory standards.

Versatile Filling Options:

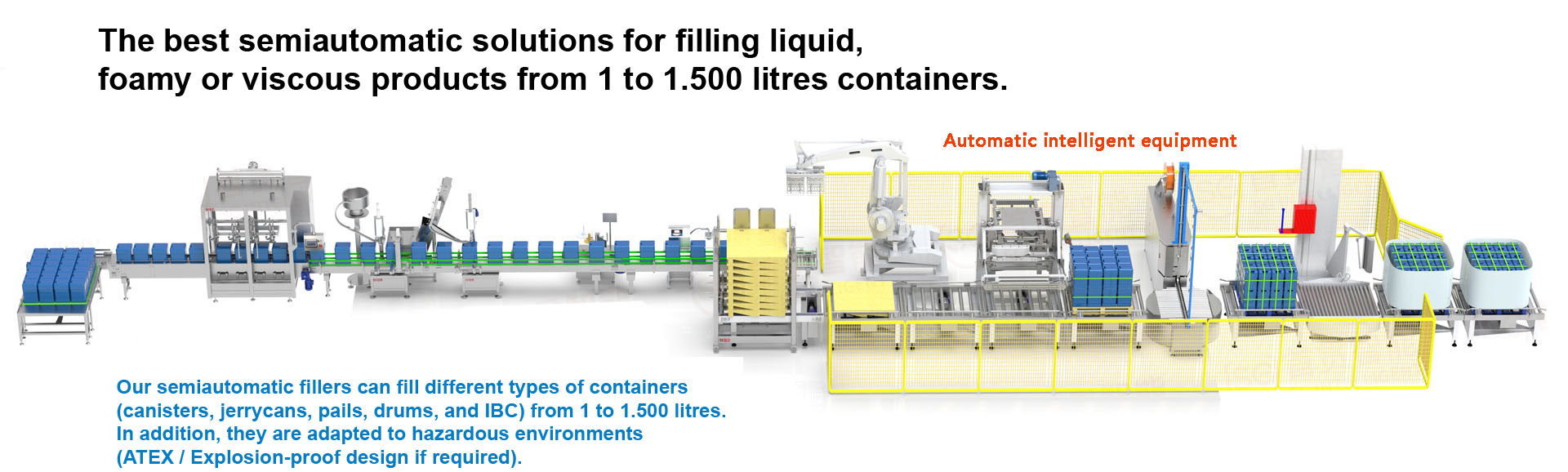

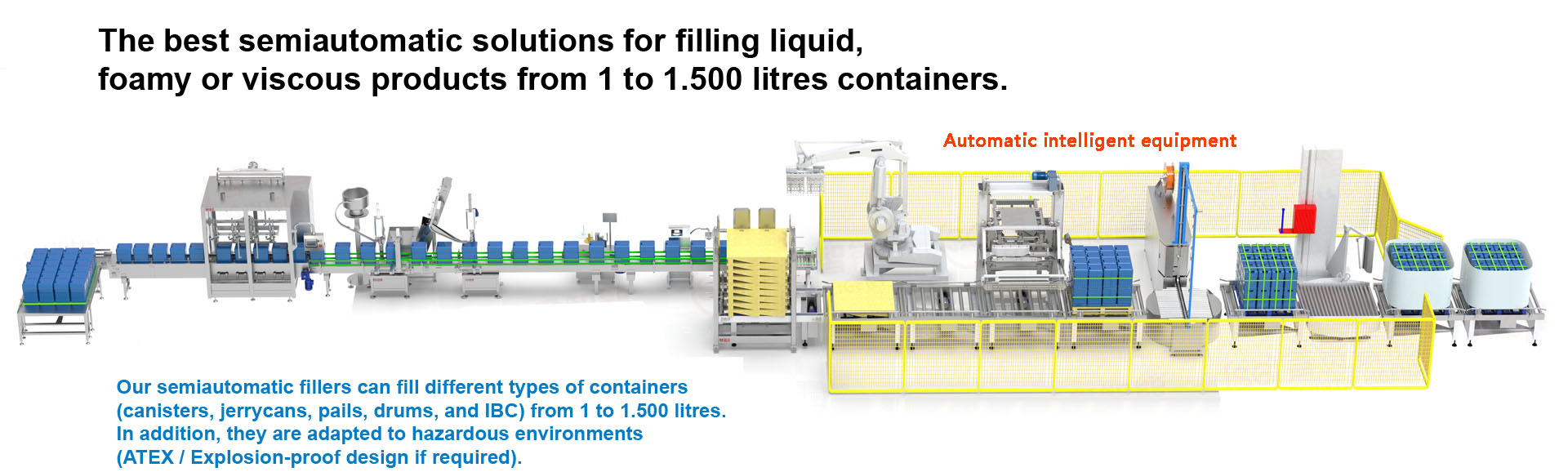

Suitable for a wide range of liquids, including viscous, corrosive, flammable, or hot/cold products.

Can handle both thin and thick liquids with minimal adjustments.

Automated Operation:

Fully programmable via PLC (Programmable Logic Controller) for seamless integration into production lines.

Features automatic container indexing, filling, and capping (if equipped).

Safety Features:

Equipped with spill containment systems to prevent leaks or drips.

Includes emergency stop buttons, interlocks, and safety guards to protect operators.

Complies with explosion-proof requirements for hazardous environments.

User-Friendly Interface:

HMI (Human-Machine Interface) allows for easy setup and monitoring of filling parameters.

Provides real-time data on fill volumes, speed, and error diagnostics.

Customizable Integration:

Can be integrated with upstream (storage tanks, pumps) and downstream (capping machines, labeling systems) equipment.

Modular design allows for scalability and adaptation to different container sizes or shapes.

Environmental Protection:

Minimizes product loss and reduces environmental impact with precise filling technology.

Can be equipped with fume extraction systems for volatile liquids.

Benefits of Rotary Arm Drum Fillers

Efficiency:

High-speed filling reduces cycle times and increases productivity.

Automated operation minimizes labor costs and human error.

Accuracy:

Precision filling ensures consistent volumes, reducing product waste and improving quality control.

Suitable for applications requiring strict adherence to regulatory standards.

Flexibility:

Can handle various container types and sizes, making it versatile for different products and batch sizes.

Easily adaptable to changes in production requirements.

Durability:

Heavy-duty construction ensures longevity and reliability in demanding industrial environments.

Low maintenance due to the absence of complex mechanical components.

Safety:

Reduces operator exposure to hazardous liquids with automated filling and spill containment systems.

Complies with safety regulations for handling flammable, corrosive, or toxic substances.

Cost Savings:

Minimizes product loss and optimizes resource usage, leading to cost efficiencies.

Reduces downtime with quick changeovers and easy cleaning.

Scalability:

Suitable for small-scale operations or large industrial facilities.

Can be expanded or reconfigured to accommodate growth or new products.

Applications of Rotary Arm Drum Fillers

Chemicals: Acids, bases, solvents, adhesives, and industrial chemicals.

Food and Beverage: Edible oils, syrups, sauces, wine, and bulk liquid food products.

Pharmaceuticals: APIs, pharmaceutical formulations, and bulk liquid medications.

Oil and Lubricants: Motor oils, greases, hydraulic fluids, and lubricants.

Paints and Coatings: Water-based and solvent-based paints, varnishes, and coatings.

Industrial Products: Cleaning agents, detergents, and specialty fluids.

Agricultural Chemicals: Fertilizers, pesticides, and crop protection products.

Example Workflow of a Rotary Arm Drum Filler

Container Indexing: A 200L drum is positioned under the rotary arm filling nozzle.

Pre-Fill Check: The system checks for container weight or volume (if applicable) and ensures proper alignment.

Filling: The rotary arm dispenses the liquid into the drum while following a preprogrammed path to avoid splashing or frothing.

Accuracy Verification: The system verifies the fill volume or weight using sensors or load cells.

Post-Fill Operations: The filled drum is capped (if equipped) and moved to the next stage of the production line.

Data Logging: The system records fill volumes, batch numbers, and other relevant data for traceability.

Customization Options

Material Handling: Integration with pumps, flow meters, or level sensors for precise liquid transfer.

Weighing Systems: High-precision load cells or checkweighers for accurate filling by weight.

Safety Features: Explosion-proof components, nitrogen blanketing, or fume extraction systems.

Automation: Robotic palletizing, capping machines, or labeling systems for fully automated workflows.

Integration: Compatibility with ERP or MES systems for inventory management and data logging.

Conclusion

A Rotary Arm Drum Filler for 200L Containers is a heavy-duty, high-efficiency solution for liquid packaging in industrial settings. Its precision, speed, and versatility make it ideal for handling a wide range of liquids, from chemicals to food products. With customizable features and robust construction, this machinery provides a reliable and scalable solution for bulk liquid packaging operations.

Immediate Order:

Website: http://m.wwbiotec.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Liquid About 200ldrum Explosion Proof Filling Machine for Solvent/Coating/Paint/Alcohol/Chemical Liquid[2025-03-31]

-

Automated IBC Filling Lines - Custom Solutions for Drums, Totes & Bulk Containers[2025-05-21]

-

Automatic Pail Filling System[2025-02-17]

-

30L Paint and Coating Filling Machine Liquid Surface Filling Machine-filling Stable and Fast-stable[2025-05-08]